Lock Plate Solutions

Products » Vehicle Security Solutions » Lock Plate Solutions

Lock plate code display solutions

Lock plate codes are required for manual tumbler assembly in lock manufacturing industry. A typical practice is multiple operators take a key of specific number and look for its lock plate codes.Then these lock plates are assembled into rotor.

Stand along device

Master device with multiple operator display units

PC as master with multiple operator display units

Lock plate code display solutions Lock plate codes are required for manual tumbler assembly in lock manufacturing industry. A typical practice is multiple operators take a key of specific number and look for its lock plate codes. Then these lock plates are assembled into rotor.

A single assembly line may require up to 6 operators for tumbler (rotor) assembly depending upon the production load. If lock plate codes are saved on computer, searching through file can be time consuming. Also, with government regulation to avoid repetitions of lock in 24 hours further slows down the production rate.

In such case, lock plate code display system give low cost but very effective solution. To cater to varying needs of customers, we have four variations in offering these solutions.

It can be easily integrated with existing embedded applications over serial port and with very easy serial AT command set.

A single stand alone device that can store lock plate codes for up to 4 products. The device can check for repeat using built-in memory and powerful processor. Each of four products can be independently configured. Some of the settings include product name, repeat check type, repeat check hours, repeat check count etc. A PC end utility enables end user to download lock plate code to device for any particular product.

Features- Supports up to four different products

- Operator can enter key number from PS2 type keyboard. (USB keyboard option available)

- Lock plate codes stored in permanent memory separately for each product

- Battery backed memory to keep track of repeated key numbers

- Facility to reset repeat logic anytime at user will Automatically keeps track of hour based repeat or count based repeat

- All settings are password protected

- Built-in 90VAC to 265VAC industry grade universal SMPS

This system includes a high-end lock plate display unit that can act as master for other node devices. As shown in the diagram, this system requires one master which stores all the data and settings and also communicates with node devices.

Operators make key number entry at all the nodes and can view the lock plate code. In this system, the data needs to be stored only in master unit and all repeat checks are also done by master unit. Hence key number entered at any one node is shown as repeated at all other nodes. This solution can be extended in case number of operators increase or decrease. This system works independently and does not require computer. Many features are similar to stand alone device.

Features- Acts as master for display node devices

- Node devices use same power supply from master device

- Can control up to 10 node devices

- Supports up to four different products

- Operator can enter key number from PS2 type keyboard. (USB keyboard option available)

- Lock plate codes stored in permanent memory separately for each product

- Battery backed memory to keep track of repeated key numbers

- Facility to reset repeat logic anytime at user will Automatically keeps track of hour based repeat or count based repeat

- All settings are password protected

- Built-in 90VAC to 265VAC industry grade universal SMPS

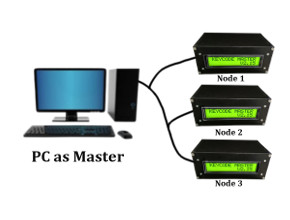

This system is same as the one mentioned above, except that the master is computer instead of embedded unit. This gives additional capacity to add more products. Since embedded device has limited memory, it can store data of four products only.

But computer can store data of more number of products and there is not theoretical limit on the number of products that can be added. The product addition can be done by customer and does not require any modification in software.

The computer is required to have one RS232 serial port for communication. An external RS232 to RS485 converter is required to convert the signals for node devices. Since node devices are externally powered, a separate 12V SMPS is required to supply power to node devices. All other working and feature set is same as earlier system.

Application Diagram of Master Device

Application Diagram of PC as Master